In the world of commercial construction and maintenance, every detail counts towards ensuring the longevity, safety, and aesthetic appeal of a building. Among these details, painting brackets might seem minor at first glance, but they hold significant importance.

This article explores the crucial role that painting brackets play in commercial structures’ overall health and functionality. From enhancing structural integrity to preventing corrosion and improving aesthetic appeal, we’ll discuss why this seemingly small task is critical to construction and maintenance protocols. Let us uncover the benefits and best practices surrounding the painting of brackets in commercial settings, highlighting its impact on project success and building lifespan.

Bracket Painting Done by Custom Painting, Inc.

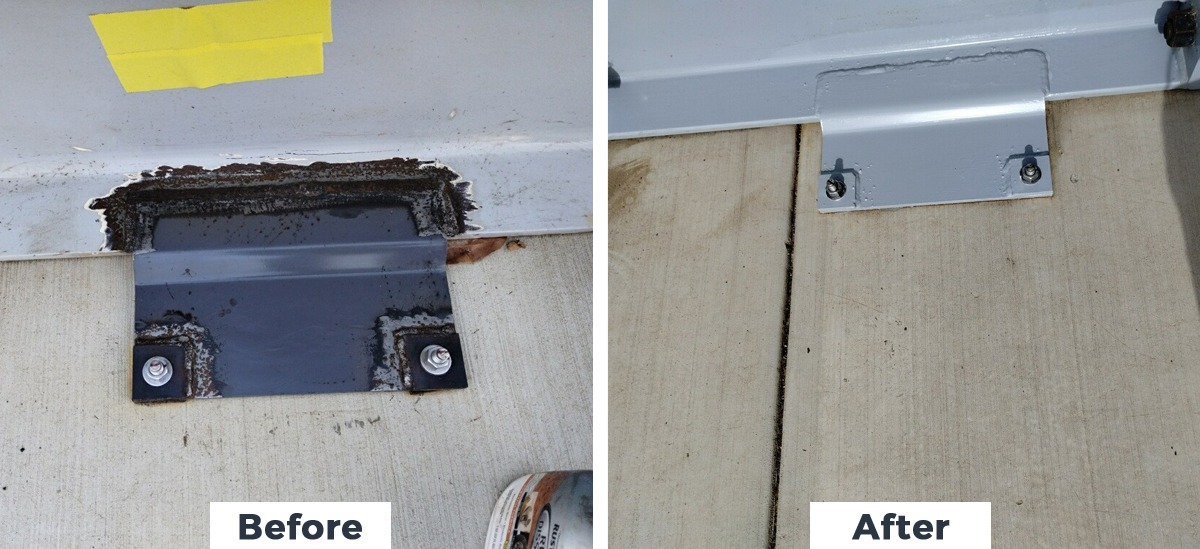

Custom Painting, Inc. recently finished a bracket painting project in Milpitas, CA. In this project, a total of 76 brackets were painted, and were all horizontal. Our company is used to this type of project as we do similar work a few times a year.

The Painting Process

Our expert painters first primed the brackets using Sherwin Williams Macropoxy 646. It is a high-solid, high-build, and fast-drying polyamide epoxy designed to protect steel in industrial environments.

Sherwin Williams Pro Industrial DTM Acrylic coating was used for the finish coat. An interior-exterior, water-based, corrosion-resistant acrylic coating was also tinted to match the adjacent metal rails where the brackets were welded. Overall, the project took two days to finish. The first day was for preparing and priming, and the second was for finishing coats.

Challenges Faced

Throughout the project, the weather was the only problem faced by the team due to the frequent rain this time of year. That is why we had a 4-day window (one day before, two days for application, and one day following) to complete the work properly. Luckily, the weather cooperated, the team had great adhesion of the primer and finish paint, and the custom color match was perfect.

In general, the bracket painting project done by Custom Painting, Inc. was a success. Read on below to learn more about the importance of painting brackets in commercial construction.

The Role of Brackets in Commercial Construction

Commercial construction involves numerous components working together to ensure building safety, functionality, and durability. Brackets play a pivotal role among these components, though they might not always be the most visible or prominent. Understanding the types of brackets used, their applications, and their importance in maintaining structural integrity is essential for anyone involved in construction and maintenance.

Definition and Types of Brackets Used in Commercial Construction

Brackets are supportive architectural elements that bear weight and reinforce connections between structural components. They can be made from various materials, including steel, aluminum, and wood, depending on their intended use and the demands of the specific construction project. There are several types of brackets used in commercial construction, including:

- L-shaped brackets: Used to support shelves or as part of framing systems.

- U-shaped brackets: Often used for piping or conduit supports.

- Custom-designed brackets: Tailored for specific structural needs or architectural aesthetics.

Examples of Bracket Applications in Structures

Brackets find their use in various applications within commercial construction, contributing to both the functionality and aesthetic aspects of a building. Examples include:

- Supporting shelving and heavy equipment: Ensuring that weight is evenly distributed and secured.

- Reinforcing beam and column connections: Critical for maintaining the overall structural framework of a building.

- Facilitating the attachment of façade elements: This bracket attaches signage, cladding, or decorative features to the main structure.

The Importance of Brackets in Ensuring Structural Integrity

The role of brackets in maintaining the structural integrity of commercial buildings cannot be overstated. They provide essential support that helps to distribute loads, resist forces, and secure connections, all of which are vital to the stability and longevity of the structure. Key points regarding their importance include:

- Preventing structural failures: By reinforcing joints and connections, brackets help prevent collapses due to weak points in the construction.

- Enhancing load-bearing capacities: Brackets contribute to the ability of a structure to support heavy weights, whether from the building itself or external factors like snow or equipment.

- Accommodating thermal expansion and contraction: Some brackets are designed to allow for movement caused by temperature changes, preventing structural damage.

Brackets may be small components in the vast commercial construction field, but their role is crucial. By supporting and reinforcing various structural elements, brackets ensure that buildings are stable, safe, and capable of meeting the demands of their intended uses.

The Purpose of Painting Brackets

In commercial construction and maintenance, painting brackets is not merely a matter of aesthetic preference but a crucial protective measure and an important design consideration. The benefits of painting brackets extend beyond their immediate appearance, offering protection against environmental damage and contributing to the building’s overall aesthetic appeal.

Protection Against Environmental Damage

One of the primary reasons for painting brackets, especially metal ones, is to shield them from environmental damage. This section delves into how painting can extend the lifespan of brackets used in construction.

- Corrosion and Rust: When metal brackets are exposed to oxygen and moisture, they are prone to corrosion and rust. This oxidative process can significantly weaken the brackets, compromising the structural integrity of the construction. Painting forms a barrier that prevents moisture and air from reaching the metal surface, thus reducing the risk of corrosion and rust.

- The Impact of Weather Conditions on Metal Brackets: Different weather conditions can affect metal brackets differently. For example, in coastal areas, the salty air can accelerate the corrosion process, while in areas with high humidity, moisture can more readily facilitate rust. Painting brackets help to protect them against such diverse weather conditions, ensuring their durability and functional integrity over time.

Aesthetic Considerations

Beyond the practical benefits of protection against environmental damage, painting brackets also play a vital role in the aesthetic integration of these elements into the overall design of the building.

- Contribution to the Overall Look of the Building: Painted brackets can be color-matched to the building’s design palette, allowing them to blend seamlessly with the overall architectural theme or to stand out as decorative elements, depending on the desired effect. This thoughtful integration can enhance the visual appeal of the structure.

- Compliance with Design and Architectural Standards: Many commercial buildings are designed with specific architectural standards, including color schemes and finishes. According to these standards, painting brackets ensure they contribute positively to the building’s appearance and comply with relevant guidelines or regulations. This compliance is particularly important in projects that achieve a certain certification or architectural design accolades.

Painting brackets serve dual purposes in commercial construction and maintenance. It not only protects these essential components from environmental damage, extending their lifespan and maintaining structural integrity, but also contributes significantly to the aesthetic value of the building. By adhering to protective measures and design standards, painting brackets demonstrates a commitment to quality and durability in construction projects.

Benefits of Painting Brackets

Painting brackets in commercial construction and maintenance offers many benefits that extend these components’ lifespan while enhancing the buildings’ overall integrity and appearance. These benefits include:

1. Improved Protection Against Environmental Damage

- Corrosion Resistance: Painting brackets provide a protective layer that shields the metal from moisture, oxygen, and pollutants, significantly reducing the risk of corrosion and rust. This protective barrier is crucial for maintaining the strength and durability of the brackets over time, especially in environments prone to harsh weather conditions or high humidity.

- Weatherproofing: Beyond just preventing rust, paint can also protect brackets from the damaging effects of UV light, rain, snow, and temperature fluctuations. This level of protection is essential for preserving the structural integrity of the brackets and, by extension, the entire building structure.

2. Improved Structural Durability and Safety

- Load-Bearing Capacity Maintenance: By preventing corrosion and weakening of the brackets, painting ensures that these components can continue to support the weight they were designed to bear effectively. This ongoing ability to handle load-bearing responsibilities is crucial for the safety and longevity of the building.

- Prevention of Premature Failure: Unprotected brackets are more susceptible to environmental damage that can lead to premature failure. Painting extends the lifespan of these brackets, ensuring they perform as intended for as long as possible, thereby avoiding potential structural issues or failures that could compromise safety.

3. Aesthetic Appeal and Design Flexibility

- Visual Cohesion: Painted brackets can be matched to the color scheme of the building or used as accent features, contributing to a cohesive and visually appealing architectural design. This flexibility allows architects and designers to incorporate functional elements like brackets into the overall aesthetic vision of the project.

- Architectural Integration: By painting brackets, they can be seamlessly integrated into the building’s design rather than standing out as purely utilitarian components. This integration is particularly important in projects where architectural aesthetics are a key consideration.

4. Economic Advantages

- Cost-Effective Maintenance: Regularly painting brackets is a cost-effective way to prevent the more significant expense of replacing corroded or damaged brackets. Painting reduces long-term maintenance and replacement costs by extending the life of these components.

- Value Preservation: A building that maintains its structural integrity and aesthetic appeal over time will likely preserve or increase its value. Painting brackets contribute to this preservation by ensuring that the functional and visual aspects remain in excellent condition.

The benefits of painting brackets in commercial construction and maintenance are multifaceted, encompassing protective, aesthetic, and economic advantages. This simple yet effective measure ensures that brackets fulfill their functional requirements while contributing positively to the building’s overall appearance and value.

Challenges in Painting Brackets

Painting brackets, while essential for the reasons outlined previously, also present several challenges that must be carefully managed to ensure the effectiveness of the paint application and the longevity of the protection it offers. These challenges range from environmental considerations to the technical aspects of the painting process itself.

1. Environmental Factors

- Adverse Weather Conditions: Painting brackets outdoors requires careful timing to avoid unfavorable weather conditions such as rain, high humidity, or extreme temperatures, affecting the paint’s ability to dry and cure properly. Such conditions can lead to poor adhesion, bubbling, or premature deterioration of the paint layer.

- Corrosive Environments: In areas with high salinity, such as coastal regions, or high levels of industrial pollution, paint coatings on brackets may degrade more rapidly. Selecting paint formulations designed to withstand these conditions is crucial but can be challenging and more costly.

2. Surface Preparation Challenges

- Thorough Cleaning Required: Effective surface preparation is key to ensuring the longevity of the paint on metal brackets. This often involves removing rust, scale, and old paint, which can be labor-intensive and time-consuming, especially for brackets with complex shapes or hard-to-reach areas.

- Proper Priming: The appropriate primer is essential for preventing corrosion and ensuring the topcoat adheres well to the metal surface. However, choosing the right primer for the specific type of metal and environmental conditions can be complex and requires specialized knowledge.

3. Application Difficulties

- Accessing Hard-to-Reach Areas: Brackets are often located in positions that are difficult to access, making the application of paint evenly across all surfaces a challenge. This is particularly true for brackets high up or behind other structural elements.

- Achieving Uniform Coverage: Ensuring that paint is applied evenly and at the correct thickness across the entire surface of a bracket can be difficult, especially when working by hand or in situ. Inconsistent coverage can lead to weak spots where corrosion might initiate.

- Proper Drying: Ensuring adequate drying of paint on brackets can be one of the more nuanced challenges in the painting process, especially when dealing with the unpredictable variables of outdoor environments or specific operational constraints of commercial construction projects. Factors affecting paint drying include weather, paint type, application thickness, temperature, and ventilation.

4. Durability and Maintenance

- Regular Maintenance Required: Painted surfaces, especially those exposed to harsh conditions, require regular inspection and maintenance to identify and address any signs of wear, such as chipping, cracking, or peeling. This ongoing maintenance requirement can be a logistical and financial challenge for large-scale projects or hard-to-reach locations.

- Choosing Long-Lasting Paints: A wide variety of paint products are available, each with different properties and levels of durability. Selecting a paint that will offer long-lasting protection while being cost-effective requires carefully balancing factors and expert advice.

Overcoming these challenges requires meticulous planning, material science, and paint technology expertise, and ongoing maintenance commitment. The selection of high-quality materials, skilled application, and regular upkeep are all essential to maximizing the protective and aesthetic benefits of painting brackets in commercial construction and maintenance projects.

Best Practices for Painting Brackets

Adopting best practices for painting brackets is crucial to ensure their longevity, functionality, and aesthetic appeal in commercial construction and maintenance. These practices encompass preparation, application, and maintenance phases, ensuring that the painted brackets withstand environmental challenges and adhere to high-quality standards.

Surface Preparation

- Thorough Cleaning: Clean the brackets thoroughly to remove dirt, grease, and other contaminants. Use appropriate cleaning agents or solvents suitable for the bracket’s material.

- Rust and Old Paint Removal: For metal brackets, remove any rust, scale, and flaking paint. Techniques such as sandblasting, wire brushing, or chemical rust removers can be effective, depending on the bracket’s condition and location.

- Apply a Suitable Primer: Choose a primer compatible with the bracket’s material and the final paint. Primer enhances paint adhesion and provides an additional layer of protection against corrosion. Ensure the primer is fully dry before proceeding to paint application.

Paint Selection

- Choose High-Quality Paint: Choose a type of paint designed for the specific conditions the brackets will face, such as moisture resistance for outdoor use or heat resistance for brackets near high-temperature areas. Quality paint ensures better durability and protection.

- Compatibility: Ensuring the paint is compatible with the material of the bracket and the primer used is vital. Incompatibility can lead to poor adhesion and faster degradation of the protective coating.

Application Techniques

- Even Application: Use brushes, rollers, or sprayers to apply paint evenly across the surface. Sprayers can be particularly effective for achieving an even coat on complex shapes or hard-to-reach areas.

- Multiple Thin Layers: Apply paint in several thin layers rather than one thick layer. Thin layers dry more uniformly and adhere better, reducing the risk of drips, sags, and bubbles.

- Proper Drying Time: Allow sufficient drying time between coats and before the bracket is put back into use. Adequate drying is crucial for the durability of the paint job.

Maintenance and Inspection

- Regular Inspections: Inspect painted brackets for signs of wear, such as chipping, cracking, or fading. Early detection of issues allows for prompt touch-ups, extending the paint job’s life.

- Touch-Up as Needed: Perform touch-ups on damaged areas as soon as possible to prevent corrosion and maintain the protective barrier.

- Record Keeping: Maintain records of paint types, colors, and application dates for each set of brackets. This information can be invaluable for maintenance planning and ensuring consistency in touch-ups or repaints.

By adhering to these best practices, the painting of brackets in commercial construction and maintenance can achieve optimal results, protecting the brackets from environmental damage, ensuring structural integrity, and contributing to the overall aesthetic quality of the construction project.

Conclusion

Throughout this discussion, we’ve highlighted the importance of painting brackets in commercial construction and maintenance. From the initial overview of the purpose and challenges associated with this task to the exploration of best practices and the intricacies of ensuring proper drying, it’s clear that painting brackets are not a mere aesthetic choice but a vital protective measure.

Key points emphasized include the critical role of painting in protecting brackets from environmental damage such as corrosion and rust, thereby enhancing the structural integrity and longevity of commercial buildings. We also touched upon the aesthetic benefits that painted brackets contribute to the overall appearance of structures, aligning them with architectural designs and standards.

Moreover, the challenges in painting brackets, particularly in achieving proper drying and adhering to best practices in application, underscore the need for meticulous planning and execution. These challenges, while significant, can be effectively managed through informed strategies and adherence to recommended guidelines.

The long-term advantages of investing in the painting of brackets extend far beyond the immediate visual appeal, offering essential protection against wear and environmental damage. This proactive approach ensures the structural durability of commercial buildings and contributes to reduced maintenance costs and enhanced property value over time.

Don’t let the complexities of commercial construction hold you back. Contact us today to discuss how we can support your project’s success. We can achieve outstanding results by combining beauty, durability, and structural integrity. Contact us now to prioritize bracket painting in your next project and discover the long-term advantages of investing in quality and care from the start. Call Custom Painting, Inc. at 925-294-8062 or fill out our contact form to message us. We look forward to collaborating with you and elevating your construction projects to new heights!