Workplace safety is essential for every employee, regardless of their industry. All workers desire to be in a safe and protected environment. Health and safety are key factors for all business sectors, including commercial painting in Dublin, to promote the wellness of employees, employers, and clients.

Workplace safety is a painting service company’s duty and moral responsibility to protect its employees and clients. Wearing safety gear is not an option but an essential requirement, and any responsible company must make sure that its paint crew wears the proper safety gear during work hours.

The common hazards of professional painting

In painting homes and commercial buildings, safety is absolutely a priority as this occupation is prone to many hazards, including:

- Prolonged standing

- Working at heights

- Slips and falls

- Falling from ladders, scaffolding, lifts,

- and other high places

- Exposure to chemicals and sanding dust

- Working in confined spaces

- Improper ventilation

- Exposure to heat and cold

- Dropped objects

- Lifting heavy or awkward objects

- Repetitive strain injury

- Electrical hazards

- Injury from specific tools and equipment

- Noise

Exposure to the following hazards may lead to several effects, such as skin allergies, respiratory problems, and injuries.

A fresh coat of paint is a relatively easy way to spruce up a home or commercial building. Painters should follow certain rules and safety measures to protect themselves and their clients. Professional painting is indeed a high-risk job, so the paint crew must be insured to protect themselves (and their clients) from injuries and property damage.

Any responsible painter should be conscientious enough to use the proper safety at all times while they are at the work site.

Personal protective equipment (PPE)

Personal protective equipment (PPE) is vital to keeping residential and commercial painters safe. Several types of paint and other supplies used by painters usually contain harsh chemicals that can cause significant health problems over time if they’re not protected. The PPE protects the crew working with paint, primers, varnishes, thinners, wood stains, and other things they may usually deal with, like cleaning products and sanding dust.

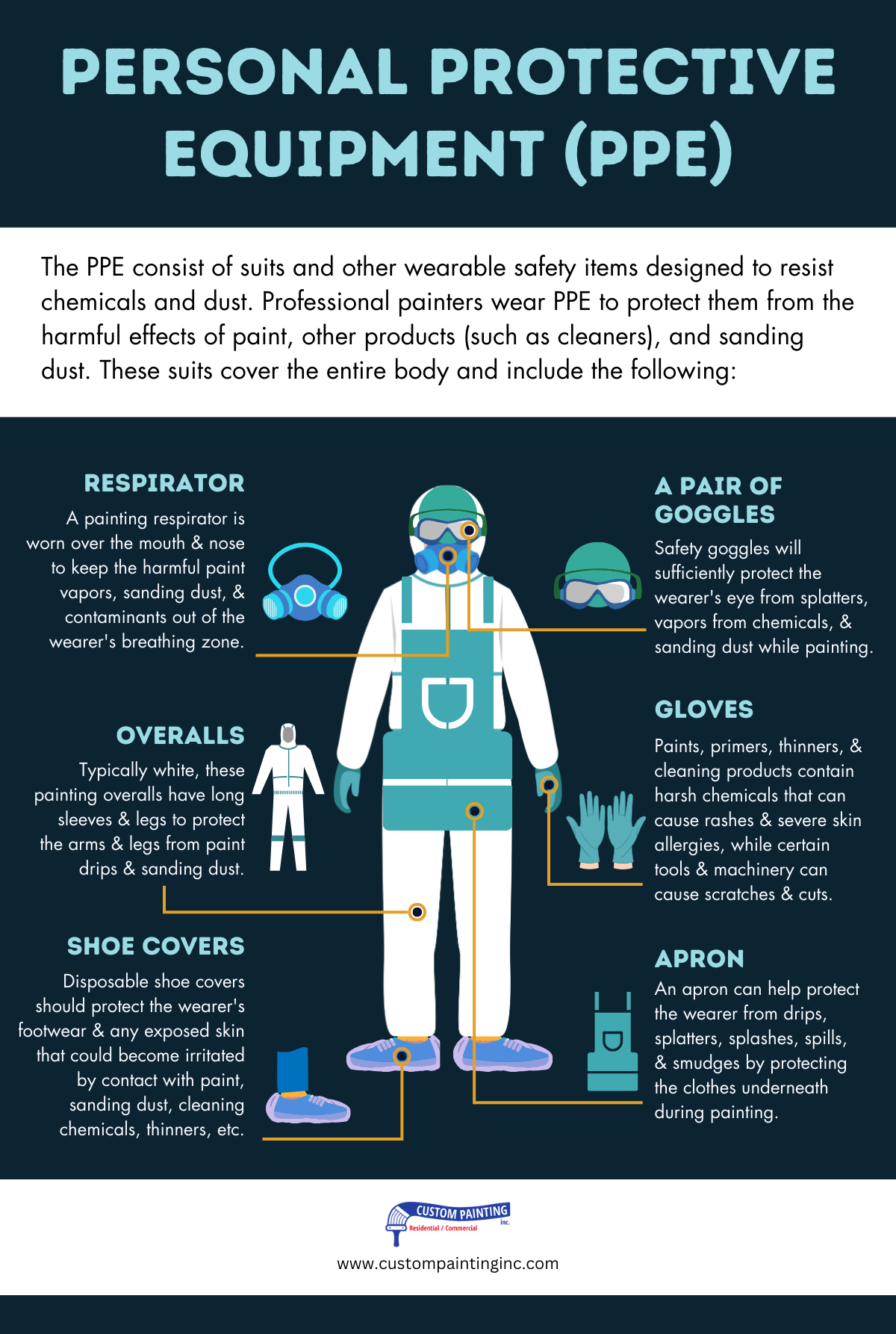

The PPEs consist of suits and other wearable safety items designed to resist chemicals and dust. Professional painters wear PPEs to protect them from the harmful effects of paint, other products (such as cleaners), and sanding dust. These suits cover the entire body and include the following:

- Overalls – Typically white, these painting overalls have long sleeves and legs to protect the arms and legs from paint drips and sanding dust. Overalls should also have a hood to protect the head from paint drips and splatters.

- Respirator – A painting respirator is worn over the mouth and nose to keep the harmful paint vapors, sanding dust, and contaminants out of the wearer’s breathing zone. The respirator should fit tightly and securely around the wearer’s face so that there’s no chance for the vapors and dust to get through the gaps in the mask.

- A pair of goggles –Safety goggles will sufficiently protect the wearer’s eye from splatters, vapors from chemicals, and sanding dust while painting. Protective goggles may also have tinted lenses to help block the sun’s ultraviolet rays when working outdoors or prevent glare when working indoors.

- Gloves – Paints, primers, thinners, and cleaning products contain harsh chemicals that can cause rashes and severe skin allergies, while certain tools and machinery can cause scratches and cuts. Suitable gloves should be worn on both hands to protect them from those elements. They should snugly fit around the fingers, palms, wrists, and knuckles so that nothing gets into them. Some gloves are disposable, while others are reusable and can be washed properly after the painter finishes with them.

- Apron – An apron can help protect the wearer from drips, splatters, splashes, spills, and smudges by protecting the clothes underneath during painting.

- Shoe covers – Disposable shoe covers should protect the wearer’s footwear and any exposed skin that could become irritated by contact with paint, sanding dust, cleaning chemicals, thinners, etc.

If someone is spray painting, the best way to protect themselves from the hazards associated with this method is to wear the following recommended PPEs:

- Eye protection should conform to American National Standards Institute (ANSI) guidelines, including a shield and a pair of goggles (if necessary).

- Respiratory protection should conform to the National Institute for Occupational Safety and Health (NIOSH) and Occupational Safety and Health Administration (OSHA) standards, including the N95 filtering face-piece respirator.

- Protective clothing that includes coveralls, long-sleeved shirts, rubber gloves, and footwear).

Safety for working at heights

Residential and commercial painting often involves working at heights, which requires raised surfaces such as step ladders, scaffolding, and mechanical lifts. Depending on the project, working conditions, and environment, it can involve many types of safety equipment. Some equipment is designed to prevent the painter from falling, while others are designed to protect the painter should a fall occur.

As in all painting and construction works and sites, wearing safety gear is obligatory and non-negotiable. When above ground level, a painter should wear the following for protection:

- Personal protective equipment (PPE) – In addition to the list of PPEs discussed earlier – the overalls, respirator, gloves, goggles, and apron – a painter working at heights should also wear the following:

- Hard hat – A hard hat protects the wearer’s head in the event of a possible impact caused by a falling object or collision during a fall.

- Harnesses and carabiners – A safety harness refers to a system of restraints that prevents the wearer from dangerous or fatal falls. The harness is usually attached to a stable and stationary object (such as a railing) through carabiners, coupling links with a safety closure. These safety gear items ensure the wearer will not hit the ground if he slips and falls.

- High-visibility safety vest or jacket – Painters working at heights should wear a reflective safety vest or jacket for visibility and protection from potential hazards. Wearing safety vests allows the worker to be seen and alert that someone is present, especially in low-visibility situations.

- Lifelines and anchors – Painters working above ground should be tethered to anchors or lifelines to ensure they can move freely but won’t fall if they slip or trip. Lifelines and anchors include all fall arrest and restraint systems that protect people working above ground instead of collective fall protection systems.

- Roof guardrails and safety rails – Barriers such as roof guardrails and safety rails must be installed to protect the workers from falling off the edge, balcony, etc. If there is a point of access to an elevated area, self-closing safety gates should also be installed together with the rails.

- Covers and domes – When the paint job is done on a roof or any top of the building, covers and domes should be erected over or around skylights or roof lights to prevent the workers from falling through them.

Who is responsible for providing protective gear for the crew?

Whether it is commercial painting or any other profession and the activity of the professional, their PPEs should be the responsibility of their employer. This is also mentioned in article R. 4321-4 of the Labor Code, which requires the employer to provide their crew with free PPEs and ensure that they function and are appropriately maintained.

Advantages of using safety gear at paint jobs

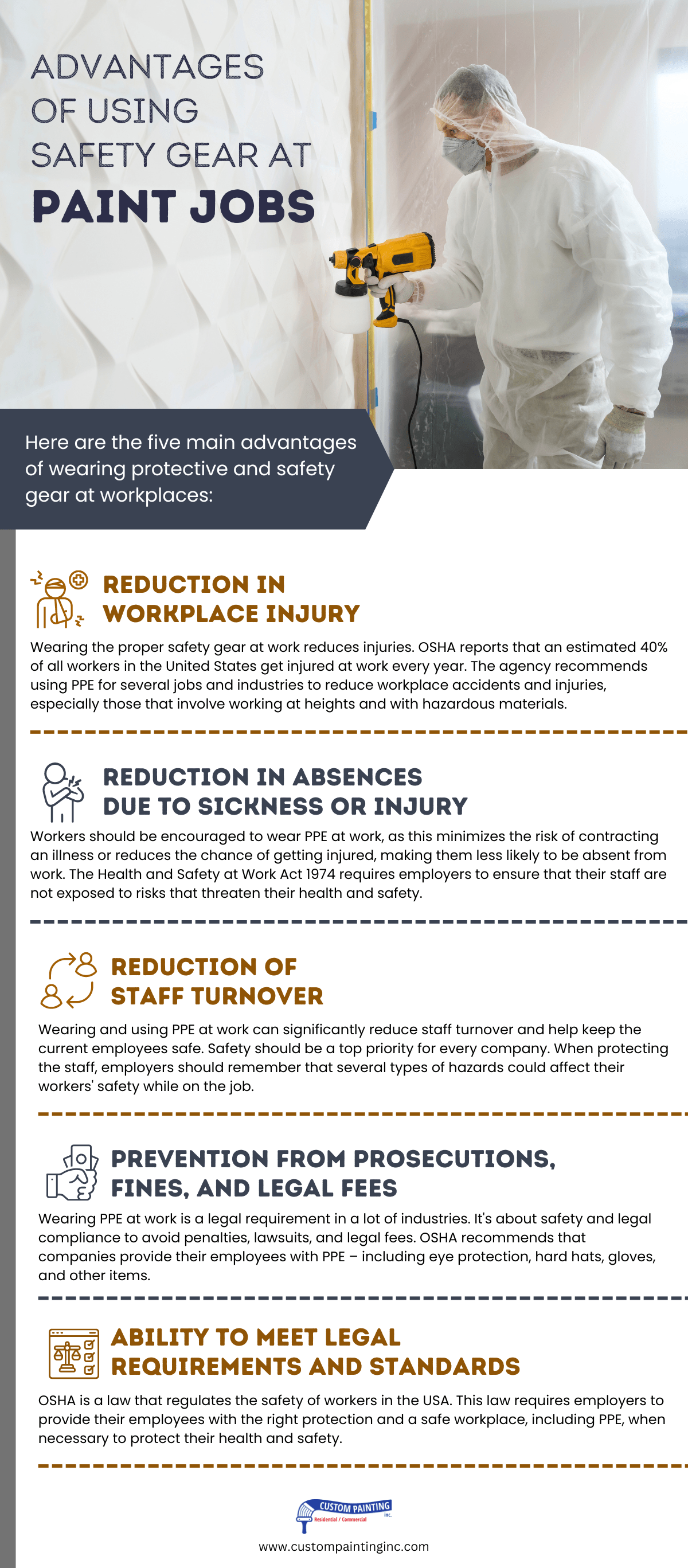

Here are the five main advantages of wearing protective and safety gear at workplaces:

1) Reduction in workplace injury

Wearing the proper safety gear at work reduces injuries. OSHA reports that an estimated 40% of all workers in the United States get injured at work every year. The agency recommends using PPEs for several jobs and industries to reduce workplace accidents and injuries, especially those that involve working at heights and with hazardous materials.

2) Reduction in absences due to sickness or injury

Workers should be encouraged to wear PPEs at work, as this minimizes the risk of contracting an illness or reduces the chance of getting injured, making them less likely to be absent from work.

The Health and Safety at Work Act 1974 requires employers to ensure that their staff are not exposed to risks that threaten their health and safety. This means employers must ensure that their crew does not come into contact with hazardous substances and materials on the job. The law also requires employers to provide PPEs for their crew if it is reasonable for them to do so.

Suppose the employer fails to provide their workers with the proper PPEs. In that case, the workers can claim compensation if the latter suffers from injury or sickness due to exposure to a hazardous material without wearing any protection.

The workers may also seek compensation if the employer fails to provide them with other proper working conditions, such as adequate ventilation or air conditioning, to prevent them from coming into contact with hazardous materials and probably getting sick.

3) Reduction of staff turnover

Wearing and using PPEs at work can significantly reduce staff turnover and help keep the current employees safe.

Safety should be a top priority for every company. When protecting the staff, employers should remember that several types of hazards could affect their workers’ safety while on the job.

In commercial painting, working at heights or exposure to paint fumes are common hazards that crews face. Wearing PPEs is one option employers can use to protect workers from such dangers.

Wearing PPEs can help reduce staff turnover rates in a company because protecting workers from hazardous conditions will help keep them safe, healthy, and happy at work.

4) Prevention from prosecutions, fines, and legal fees

Wearing PPEs at work is a legal requirement in a lot of industries. It’s about safety and legal compliance to avoid penalties, lawsuits, and legal fees.

OSHA recommends that companies provide their employees with PPEs – including eye protection, hard hats, gloves, and other items. The employees should also wear PPEs when working in hazardous conditions or near heavy equipment. The PPE aims to help protect workers against illnesses or injuries during their jobs.

There have been a lot of cases where workers are injured or get sick on the job due to poor working conditions, defective products, or poorly designed equipment. These injuries and illnesses were often preventable had the employer taken safety precautions.

For example, if you are a painter and you are injured while wearing PPE at work, it can be hard for you to prove that your employer’s negligence caused your injury or sickness. But if you are not wearing the proper safety gear when you get injured or sick on the job, it becomes a lot easier for your lawyer to argue that your employer should have provided you with proper protection from harm.

Employers can face serious legal consequences if they fail to equip their workers with the right protective gear adequately. OSHA may issue a citation or fines if the employees get sick or injured because they weren’t provided the proper protective gear. This is why employers must provide their workers with all the PPEs they need, especially if they work on dangerous projects or in hazardous environments.

5) Ability to meet legal requirements and standards

OSHA is a law that regulates the safety of workers in the USA. This law requires employers to provide their employees with the right protection and a safe workplace, including PPEs, when necessary to protect their health and safety.

OSHA states that employers must provide their employees with proper PPEs when there is a risk or danger to their health and safety during the job.

In addition to PPEs, employers must provide adequate training for employees who use PPEs as it helps them understand why they need them and how to use them properly so that they do their job properly. Also, employers must ensure that any PPE supplied is adequately maintained to function well if needed during an emergency.

Conclusion

Personal protective equipment, or PPE, can protect the paint crew from injuries or illnesses. In industries such as commercial painting, employees who work at heights, with paint fumes, or with electric wires are required to wear PPEs such as overalls, high-visibility vests, hard hats, safety goggles, gloves, harnesses, etc. They are designed to protect the workers’ bodies from potential harm.

When used correctly and in conjunction with other safety procedures, these safety gear items can effectively prevent injuries or infections. The best painters in the Bay Area always put safety as a top priority in every project they tackle for a successful paint job.

Suppose you are considering commercial painting at your Dublin facility. In that case, you know, hiring a painting company that is concerned with their clients, as well as their employees, safety is one of the more important subjects to discuss. Custom Painting, Inc. has been painting commercial properties and homes in the Bay Area for over 40 years. During those years, they have placed safety at the forefront, along with customer satisfaction. You may reach us by calling 925-294-8062 to schedule an appointment or fill out the Contact form on the website. Someone will get back to you as soon as possible.